RITAG

RITAG - Valve Experience. Made in Germany

Whether swing check valves, high pressure valves or sampling systems: RITAG enjoys an excellent reputation worldwide as a specialist in industrial valves. The valves are produced in Germany and installed world wide. Our team of dedicated professionals are the core of our engineering competence and they like to share their knowledge and know-how with our industry customers.

RITAG check valves, sampling valves and bottom valves are very thoroughly checked out. We maintain a broad range of instruments for that purpose, ready to use on demand or request. Pressure and leak tests are included, just like low-temperature applications, flow simulations or testing for cleanability.

RITAG SR Type

Brass, Bronze, Cast Iron

| Press. Rating : | PN 6 to 16 |

| Temp. : | Up to 250 ºC |

| Sizes : | DN 15 to 200 |

RITAG SR Type

Carbon Steel

| Press. Rating : | PN 6 to 160 Class 150 to 1500 |

| Temp. : | Up to 450 ºC |

| Sizes : | DN 15 to 300 |

RITAG SR Type

Stainless Steel

| Press. Rating : | PN 6 to 160 Class 150 to 1500 |

| Temp. : | Up to 500 ºC |

| Sizes : | DN 15 to 200 |

RITAG SR Type

PTFE, Titanium, Alloy

| Press. Rating : | PN 6 to 40 Class 150 to 300 |

| Temp. : | Up to 400 ºC |

| Sizes : | DN 15 to 100 |

RITAG ZRK Type

Bronze

| Press. Rating : | PN 6 to 16 |

| Temp. : | Up to 300 ºC |

| Sizes : | DN 50 to 500 |

RITAG ZRK Type

Carbon Steel

| Press. Rating : | PN 6 to 40 Class 150 |

| Temp. : | Up to 450 ºC |

| Sizes : | DN 50 to 500 |

RITAG ZRK Type

Stainless Steel

| Press. Rating : | PN 6 to 40 Class 150 |

| Temp. : | Up to 400 ºC |

| Sizes : | DN 50 to 500 |

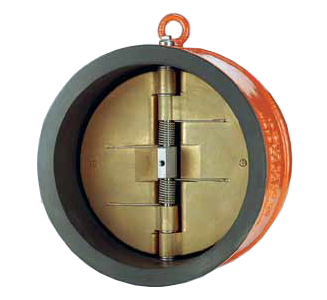

RITAG ZRD 4 / ZRD AB

Bronze

| Press. Rating : | PN 6 to 16 Class 150 to 300 |

| Temp. : | Up to 300 ºC |

| Sizes : | DN 50 to 1000 |

RITAG ZRD G / ZRD DCI

Ductile Cast Iron

| Press. Rating : | PN 6 to 16 Class 150 |

| Temp. : | Up to 300 ºC |

| Sizes : | DN 50 to 1000 |

RITAG ZRD 1 / ZRD CS

Carbon Steel

| Press. Rating : | PN 6 to 160 Class 150 to 2500 |

| Temp. : | Up to 450 ºC |

| Sizes : | DN 50 to 1000 |

RITAG ZRD 2 / ZRD 3 / ZRD SS

Stainless Steel

| Press. Rating : | PN 6 to 160 Class 150 to 2500 |

| Temp. : | Up to 400 ºC |

| Sizes : | DN 50 to 1000 |

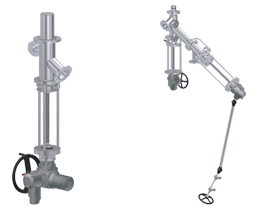

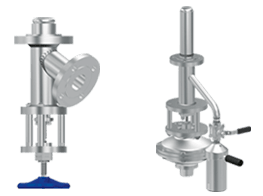

RITAG BA and BAS Bottom Valves

Cone Model

| Disc valve types are available in a design that opens into the tank or opens into the valve. |

RITAG BV and BVS Bottom Valves

Piston Model

| Type BV piston valves as a rule open into the valve and therefore keep the entire cross-section of the housing open. |

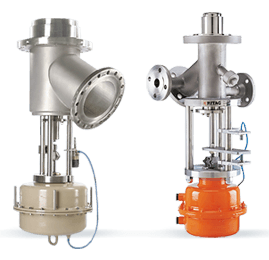

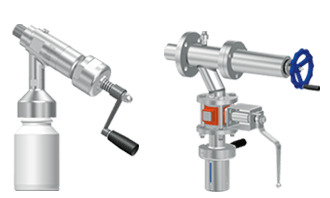

RITAG BAP Sampling Valves

Cone Version

| Designed as the cost-efficient container sampling option. |

RITAG BVP Sampling Valves

Piston Version

| The entire line diameter can be cleared by the return of the piston. |

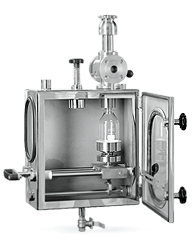

RITAG EPOS Sampling Systems

| A modular design and offer a wide range of combination options for all requirements. |

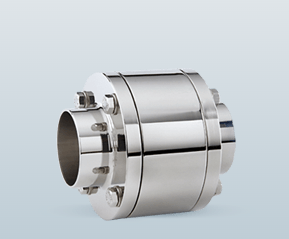

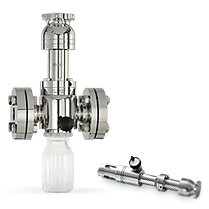

RITAG Clean Service Valves

| RITAG has designed valve type solutions that have been developed for Clean-In-Place (CIP) cleaning approaches. The EHEDG standards were followed. |

Our tests, with the appropriate tests and approvals for our industry valves, will always provide you with the desired safety. The quality, which is based on our stable processes, has been documented with all the relevant certificates.

RITAG check valves, sampling valves and bottom valves are very thoroughly checked out. We maintain a broad range of instruments for that purpose, ready to use on demand or request.

Pressure and leak tests are included, just like low-temperature applications, flow simulations or testing for cleanability.

The acceptance includes standard material testing and on-site inspections, which will be certified according to EN 10204. In addition to the standards intended in the standard testing further special tests, such as dye penetration testing, magnetic particle inspection, ultrasonic examination, radiation testing or materials identification (PMI) can be commissioned.

- PMI Positive Material Identification

- RT Radiographic Test

- UT Ultrasonic Testing

- DPT/LPT Dye Penetration Test/Liquid Penetration Test

- MPI Magnetic Particle Inspection

- CRYO Cryogenic Leakage Test

- ST Shell Test

- LPCT Low Pressure Closure Test

- HPCT High Pressure Closure Test

- DC Dimensional Check

- DFTDry Film Thickness