SCHROEDER

SCHROEDER - Reliable Pump Protection

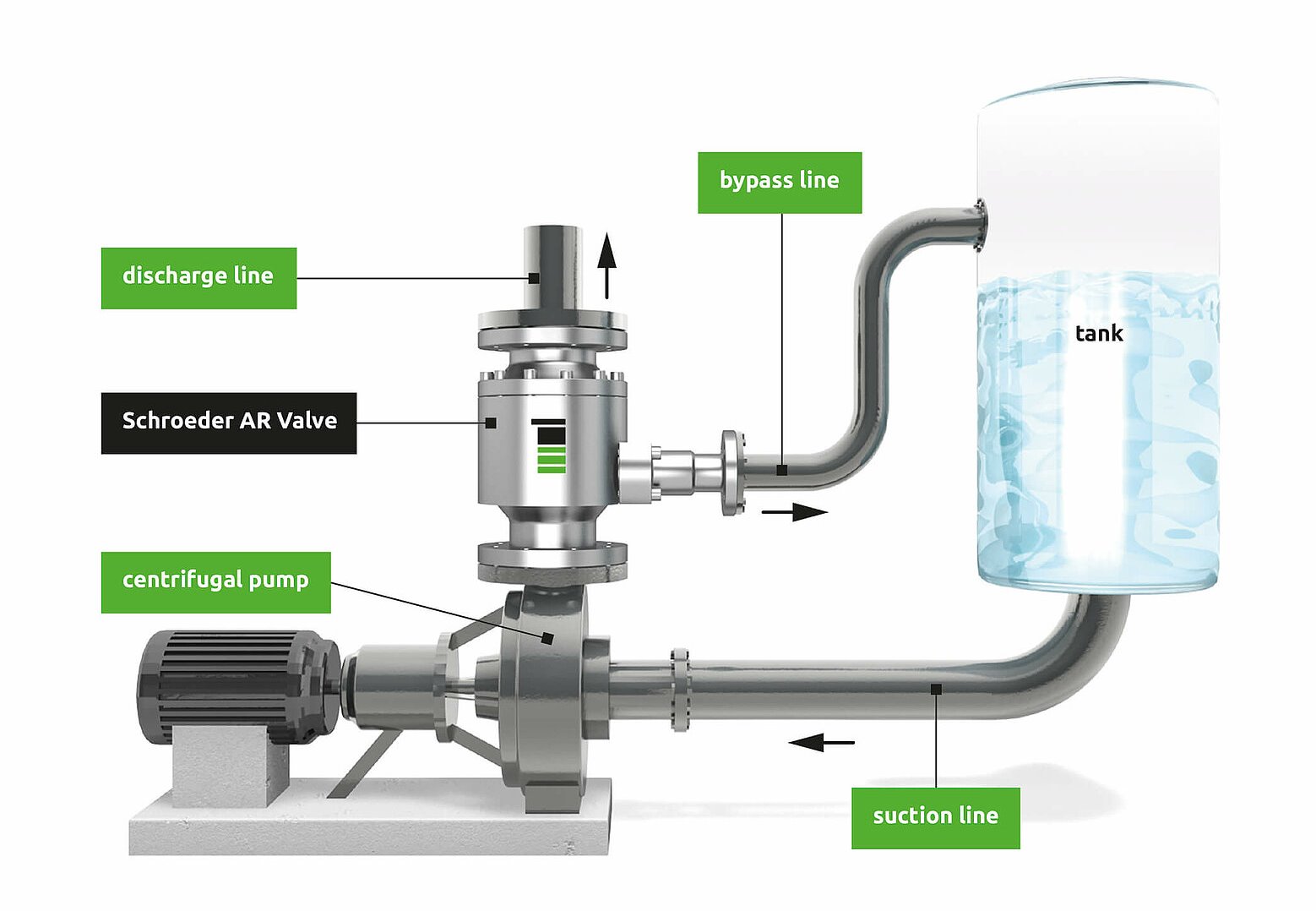

Despite its long and cumbersome name, the Automatic Recirculation Valve (AR Valve) is an inconspicuous element in the centrifugal pump circuit. The AR Valve’s main purpose is to ensure that a pre-determined minimum flow through a centrifugal pump is guaranteed at all times. This is important because centrifugal pumps operating below the minimum flow suffer from overheating, vibrations and cavitation and can be permanently damaged and even completely destroyed if they run dry.

Like a fuse in a power circuit – the AR Valve is essential for the safety of a plant.

Operating principle

The Schroeder AR Valves are mounted on the discharge branch of the pump or in the discharge line right after the pump. The bypass branch of the valve is connected to the bypass line. The valve is solely flow-controlled. In start-up conditions with closed main line, the valve will allow the minimum flow through the bypass. As the discharge line is open, the valve will modulate flow between the process and the bypass branch. As soon as the process demand exceeds the minimum flow, the bypass will fully close and all flow through the valve is sent to process. If the actual process flowrate falls below the required minimum flow, the valve automatically opens the bypass and the determined flowrate recirculates through the bypass line to a tank or vessel.

Advantages

- Combination of main line check valve and automatic bypass flow control

- Perfect backflow preventer in main direction

- Ideal guard against damages from overheating and cavitation

- Very reliable, extremely low-maintenance and particularly durable

- Reduces downtime and increases system efficiency

- No auxiliary power supply or measurement technology required

- Guaranteed lower system and operating costs

- Also suitable for variable rpm pumps

Technical Support and Quality Control

Quality products should be accompanied by excellent service, which is why Customer Service has always been a central pillar of our culture. Schroeder Valves is known for comprehensive support and fast response concerning both the procurement process as well as maintenance and repairs. We offer a self-contained package – from advice in the product right up to the documentation.

To ensure 100 % quality, we have implemented a unique test center. Prior to leaving our factory, each valve is hydraulically tested to ensure and document the highest degree of quality and functionality.

Total : 4 photo(s)