ADCA

ADCA - Specialist for Steam Equipment and Heat Recovery Solutions

Valsteam ADCA has grown up to become steam equipment and valve manufacturers, using the knowledge acquired along the years, and can now assure the complete production cycle: design, machining, welding, assembly, tests, quality and packaging for a very wide range of products.

ADCA has two production facilities with a total covered area of 18 000 m2, located in a small village in the ocean side of Portugal, and are currently growing again, expanding their main production facility. The team today consists of almost 100 people that together drive the Portuguese caravel along the five continents and more than 100 countries.

.jpg) |

.png) |

.png) |

.jpg) |

.jpg) |

.jpg) |

.jpg) |

STEAM TRAPS / AIR TRAPS

ADCA Thermodynamic Steam Traps

[ Disc Traps ]

| Materials : | Carbon steel, Stainless Steel |

| Diff. Press. : | Up to 46 Bar |

| Temp. : | Up to 400 ºC |

| Sizes : | 3/8” to 1” – DN 10 to 25 |

ADCA Thermostatic Steam Traps

[ Capsule Type ]

| Materials : | Carbon steel, Brass, Stainless Steel |

| Diff. Press. : | Up to 22 Bar |

| Temp. : | Up to 250 ºC |

| Sizes : | 1/4” to 2” – DN 8 to 50 |

ADCA Thermostatic Steam Traps

[ Bimetallic Type ]

| Materials : | Carbon steel, Brass, Stainless Steel |

| Diff. Press. : | Up to 160 Bar |

| Temp. : | Up to 525 ºC |

| Sizes : | 1/2” to 5” – DN 15 to 125 |

ADCA Float Steam Traps

[ Float with Bimetallic Air Venting ]

| Materials : | SG iron, Carbon steel, Stainless Steel |

| Diff. Press. : | Up to 32 Bar |

| Temp. : | Up to 250 ºC |

| Sizes : | 1/2” to 6” – DN 15 to 150 |

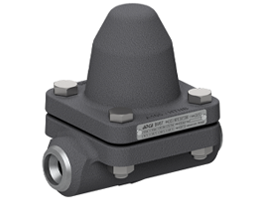

ADCA Inverted Bucket Steam Traps

| Materials : | SG iron, Carbon steel, Stainless Steel |

| Diff. Press. : | Up to 40 Bar |

| Temp. : | Up to 400 ºC |

| Sizes : | 1/2” to 2” – DN 15 to 50 |

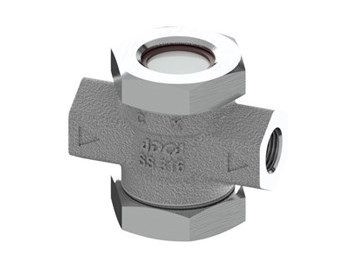

ADCA Universal Connection Steam Traps

| Materials : | Stainless Steel |

| Diff. Press. : | Up to 32 Bar |

| Temp. : | Up to 250 ºC |

| Sizes : | 1/2” to 1” – DN 15 to 25 |

ADCA Air Traps

| Materials : | SG iron, Carbon steel, Stainless Steel |

| Diff. Press. : | Up to 32 Bar |

| Temp. : | Up to 250 ºC |

| Sizes : | 1/2” to 2” – DN 15 to 50 |

ADCA Ultrasonic Trap Tester

Hand held ABS pistol type ultrasonic processor, stainless steel sensor enclosures.HEAT RECOVERY SOLUTIONS

ADCA Condensate Mechanical Pumps

[ Steam Powered Pumps ]

| Materials : | Carbon steel, Stainless Steel |

| Motive Press. : | Up to 10 Bar |

| Capacity : | 18,240 kg/h |

| Sizes : | 1 x DN25x25 to 3 x DN 80x50 |

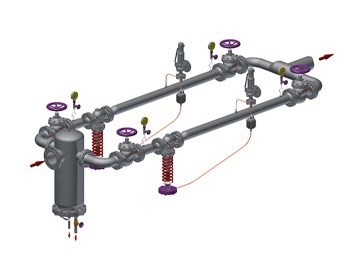

ADCA Condensate Return Packaged Units

Condensate recovery solutions are specifically designed to efficiently remove and recover condensate under all operating conditions.

ADCA Heat Exchangers

Highly efficient, flexible heat exchange solutions for heating using steam, all to your exact requirments.

ADCA Flash Vessels

Flash vessels are used to recover energy by separating flash steam from the top of the vessel to any appropriate low-pressure steam equipment.

ADCA Deaerators

Deaerators are designed to heat boiler feed water and reduce oxygen and carbon dioxide levels.

ADCA Blowdown Vessels

Blowdown vessels are used in modern boiler houses to cool hot wastewater and steam boiler blowdown before discharging them into a pit or drain.

ADCA Steam Injectors

Direct steam injectors designed for rapid heating of still or flowing mediums, inside basins and vessels.

PRESSURE REGULATORS

ADCA Self-Actuating

Pressure Reducing Valves

| Materials : | SG iron, Carbon steel, Stainless Steel |

| Press. Range : | 0.15 to 18 Bar |

| Temp. : | Up to 250 ºC |

| Sizes : | 1/2” to 6” – DN 15 to 150 |

ADCA Direct Acting

Pressure Reducing Valves

| Materials : | Carbon steel, Stainless Steel |

| Press. Range : | 0.2 to 200 Bar |

| Temp. : | Up to 210 ºC |

| Sizes : | 1/4” to 2” – DN 8 to 50 |

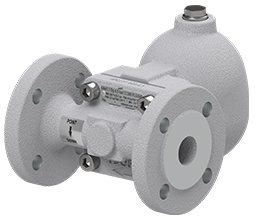

ADCA Pilot Operated

Pressure Reducing Valves

| Materials : | Carbon steel, Stainless Steel |

| Press. Range : | 0.07 to 17 Bar |

| Temp. : | Up to 300 ºC |

| Sizes : | 1/4” to 4” – DN 8 to 100 |

ADCA Pressure Reducing Station

The pressure-reducing station are balanced, single-seated valves functioning as proportional controllers that do not need energy from outside.

ADCA Pressure Sustaining Valves

| Materials : | Carbon steel, Stainless Steel |

| Press. Range : | 50 Bar |

| Temp. : | Up to 300 ºC |

| Sizes : | 1/4” to 4” – DN 8 to 100 |

ADCA Tank Blanketing Valves

| Materials : | Stainless Steel, |

| Press. Range : | 12 Bar |

| Temp. : | Up to 130 ºC |

| Sizes : | 1/2” to 1” – DN 15 to 25 |

PURE STEAM EQUIPMENT

ADCAPure Steam Traps

| Materials : | Stainless Steel, |

| Diff. Press. : | Up to 6 Bar |

| Temp. : | Up to 165 ºC |

| Sizes : | 1/2” to 1-1/2” – DN 15 to 40 |

ADCAPure Pressure Regulators

From the simplest, direct acting valves, to the most sophisticated pilot operated valves, we assure a wide range of options, varying in different types of construction

AADCAPure Control Valvess

Hygienic control valves offer different solutions for controlling temperature, level, pressure, and humidity.

ADCAPure Safety Valves

| Materials : | Stainless Steel, |

| Diff. Press. : | 16 Bar |

| Temp. : | Up to 180 ºC |

| Sizes : | DN 20 x 25 to DN 40 x 50 |

ADCAPure Steam Filters

High-efficiency filters are used to remove contaminated particles from gases such as steam and compressed air. Available with 1, 5 or 25 micron absolute rating.

ADCAPure Separators

Both types of baffle/centrifugal separators can offer to remove moisture from steam pipelines to improve heat transfer efficiency.

ADCAPure Sample Coolers

Consists of a helical-coil heat exchanger used to take samples quickly and safely from steam generators, clean or pure steam systems, WFI, and other high purity mediums.

ADCAPure Pipeline Ancillaries

Sight glasses, vacuum breakers, ball valves, and other sanitary ancillaries that are vital to the functioning of high-purity fluid systems.

CONTROL VALVES

ADCA Two-Way Control Valves

| Materials : | SG iron, Carbon steel, Stainless Steel |

| Flow Rates : | Kvs 0.1 to 630 |

| Sizes : | DN 15 to 200 |

ADCA Thermostatic Steam Traps

[ Capsule Type ]

| Materials : | SG iron, Carbon steel, Stainless Steel |

| Flow Rates : | Kvs 4 to 330 |

| Sizes : | DN 15 to 150 |

ADCA Valves for Special Applications

Bottom blowdown valves, continuous blowdown valves, two-way overflow valves

ADCA Actuators

Pneumatic multi-spring actuators, electric linear actuators

ADCA Self-Acting

Temperature Control Valves

Direct-acting temperature control systems where the valve closes/open when temperature rise.

ADCA Conductivity Probes and

TDS Controller

The ADCATrol conductivity probe is typically used in steam applications to measure the conductivity of superheated boiler water, condensate or feedwater.

ADCA Instrumentation and

Accessories

Controller/limitter, positioner, pressure transmitters, solenoid valves, air filter regulators, resistance temperature sensors,

PIPELINE ANCILLARIES

ADCA Automatic Air Vent for

Liquid Systems

| Materials : | Carbon steel, Stainless Steel |

| Pressure. : | Up to 32 Bar |

| Temp. : | Up to 250 ºC |

| Sizes : | 1/2” to 3” – DN 15 to 80 |

ADCA Vacuum Breakers

| Materials : | Stainless Steel, |

| Pressure. : | Up to 21 Bar |

| Temp. : | Up to 4000 ºC |

| Sizes : | 1/2” to 1” |

ADCA Pipeline Strainers

| Materials : | Carbon steel, Stainless Steel |

| Pressure. : | Up to 100 Bar |

| Temp. : | Up to 440 ºC |

| Sizes : | 1/2” to 4” – DN 15 to 100 |

ADCA Sight Glasses

| Materials : | Carbon steel, Brass, Stainless Steel |

| Pressure. : | Up to 40 Bar |

| Temp. : | Up to 280 ºC |

| Sizes : | 1/2” to 2” – DN 15 to 50 |

ADCA Non Return Valves

| Materials : | Stainless Steel, |

| Pressure. : | Up to 40 Bar |

| Temp. : | Up to 300 ºC |

| Sizes : | 1/4” to 4” – DN 8 to 100 |

ADCA Isolation Valves

Three piece ball valves, wafer ball valves, bellow seal stop valves

ADCA Pressure and Level Gauges

Level gauge valves, pressure gauges high-pressure needle valves

QUALITY CONTROL AND TESTING

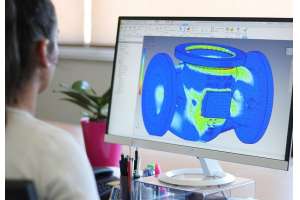

Products are meticulously tested and rigorously controlled throughout the manufacturing process granting the highest level of quality and reliability. From raw material control via spectrometry and 3D measuring to final product testing.

The substantial investment in stage-of-the-art machinery allows us to achieve a high level of quality and reliability, as well as a natural increase in productivity and decrease in delivery times, especially for non-standard series of products.

As One-Stop-Shop and a full service manufacturer, we assure the complete production cycle: design, machining, welding, assembly, tests, quality and packaging.

A complex system that depends on the high technology we use.

Total : 8 photo(s)